Comprehending the Key Components and Repair Service Techniques for Product Packaging Machine Maintenance

Effective maintenance of product packaging devices rests on a detailed understanding of their vital elements, including the structure, drive system, and sealing devices. Recognizing usual maintenance issues, coupled with the execution of preventative methods and fixing techniques, can considerably enhance equipment dependability. Additionally, the choice of fixing techniques, consisting of using OEM components and the significance of certified professionals, plays a vital function in minimizing downtime. To really grasp the ins and outs of these systems and their upkeep, one should take into consideration the broader effects of overlooking these crucial practices.

Key Elements of Packaging Devices

Product packaging machines consist of several key components that collaborate to ensure effective and efficient packaging processes. At the core of these machines is the framework, which gives structural stability and houses the different operating parts. The drive system, usually a mix of electric motors and equipments, assists in the movement of components, making it possible for accurate procedure throughout the product packaging cycle.

An additional vital element is the conveyor system, which delivers items with different stages of the product packaging procedure. This is usually enhanced by sensing units and controls that keep an eye on the setting and rate of products, making sure synchronization and lessening errors. The filling system is critical for properly giving the ideal amount of product right into plans, whether in liquid, powder, or strong type.

Sealing mechanisms, consisting of warm sealers or sticky applicators, play an important duty in safeguarding bundles, preventing contamination and expanding life span. Additionally, classifying systems are important for offering essential product info, guaranteeing conformity with guidelines. Finally, the control board, geared up with user-friendly interfaces, allows operators to handle equipment functions, display efficiency, and make changes as required, guaranteeing ideal efficiency and performance in product packaging operations.

Typical Maintenance Concerns

Effective procedure of product packaging equipments depends heavily on regular maintenance to avoid usual issues that can interfere with manufacturing. Among these issues, mechanical wear and tear prevails, particularly in parts like seals, conveyors, and motors, which can cause unanticipated downtimes. Additionally, misalignment of parts can result in ineffective operation, creating products to be incorrectly packaged or damaged during the process.

An additional common maintenance concern includes the accumulation of dirt and particles, which can disrupt the maker's sensing units and relocating parts. packaging machine repair service. This not just impacts efficiency yet can likewise posture security dangers. Lubrication failings can lead to increased friction, resulting in overheating and ultimate component failing.

Electric issues, frequently coming from loose connections or worn-out wiring, can interrupt equipment functions, bring about significant production delays. Software program glitches due to obsolete programs or improper configurations can impede the device's procedure, necessitating instant intervention. Attending to these typical upkeep issues proactively is important for making sure ideal efficiency and long life of packaging go equipment.

Preventative Upkeep Strategies

Carrying out preventative maintenance strategies is important for sustaining the efficiency and integrity of packaging devices. These techniques incorporate a systematic method to look at this site upkeep, concentrating on the routine inspection and servicing of equipment to preempt prospective failures. By sticking to an arranged maintenance program, drivers can determine deterioration on elements before they cause considerable malfunctions.

Trick components of a preventative upkeep approach consist of regular examinations, lubrication, part, and cleansing substitutes based upon producer recommendations. Utilizing checklists can streamline this procedure, guaranteeing that no necessary tasks are neglected. In addition, keeping precise documents of maintenance tasks aids in tracking the equipment's performance over time, helping with informed decision-making concerning future upkeep requirements.

Training staff on the value of preventative maintenance enhances conformity and promotes a society of positive treatment. Executing an anticipating upkeep element, using data analytics and sensor innovation, can even more enhance machinery efficiency by predicting failings prior to they occur.

Troubleshooting Methods

When confronted with breakdowns or inefficiencies in product packaging makers, employing methodical troubleshooting strategies is essential for identifying and dealing with problems quickly. The initial step in effective troubleshooting is to develop a clear understanding of the equipment's functional criteria and efficiency metrics. This includes assessing the machine's specs, in addition to any error codes or signals presented.

Next, drivers must conduct an aesthetic examination, examining for apparent indications of wear, damages, or misalignment. This commonly includes checking out equipments, belts, and sensors to pinpoint prospective reasons of malfunction. Collecting operational information, such as production rates and downtime logs, can likewise provide insights right into recurring problems.

When possible problems are determined, making use of a logical method to separate the origin is important. This might call for testing individual elements or systems in a regulated fashion. Participating in my review here discussions with operators who engage with the equipment routinely can produce beneficial responses about unusual habits or patterns.

Repair and Substitute Ideal Practices

A detailed understanding of fixing and substitute ideal methods is important for preserving the durability and efficiency of packaging machines. Routinely evaluating the problem of equipment elements enables for timely intervention, avoiding more significant concerns that can cause expensive downtimes.

When repair work are required, it is vital to utilize OEM (Original Devices Supplier) components to guarantee compatibility and performance. This not only protects the honesty of the maker however likewise upholds guarantee arrangements. In addition, it is advisable to maintain a supply of vital extra parts to promote quick replacements and reduce functional disturbances.

For complex repair services, involving certified professionals with specialized training in packaging machinery is suggested. They have the experience to diagnose problems accurately and carry out repairs effectively. Recording all repair activities and parts substitutes is essential for preserving a thorough upkeep history, which can aid in future troubleshooting.

Finally, applying a proactive approach, including routine examinations and anticipating upkeep techniques, enhances the reliability of packaging devices. By adhering to these finest techniques, organizations can ensure optimal machine performance, decrease operational dangers, and prolong tools lifespan.

Final Thought

In conclusion, a detailed understanding of packaging device components and reliable upkeep techniques is crucial for optimum performance. By executing these practices, companies can make certain the longevity and effectiveness of product packaging equipments, ultimately contributing to improved operational efficiency and minimized prices (packaging machine repair service).

Reliable upkeep of product packaging machines hinges on an extensive understanding of their crucial parts, consisting of the frame, drive system, and sealing mechanisms.Effective operation of packaging devices depends heavily on regular maintenance to avoid common problems that can interfere with manufacturing.Applying preventative upkeep strategies is important for maintaining the performance and integrity of product packaging makers. In addition, keeping accurate records of maintenance activities aids in tracking the device's efficiency over time, helping with notified decision-making relating to future upkeep requirements.

Spencer Elden Then & Now!

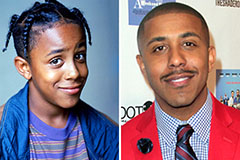

Spencer Elden Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Bernadette Peters Then & Now!

Bernadette Peters Then & Now!